rockwell hardness test calibration lab report|rockwell hardness tester calibration cost : distribution The purpose of this Guide is to explain the causes of variability in Rockwell hardness test results and to supplenment the information given in test method standards with . WEBPandora radio is the personalized internet radio service that helps you find new music based on your old and current favorites. Create custom web radio stations, listen free.

{plog:ftitle_list}

WEBSmart Fit, Maringá. 3,623 likes · 3 talking about this · 9,499 were here.

The hardness test is a mechanical test for material properties which are used in engineering design, analysis of structures and material development. The hardness test is performed to .TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .

The purpose of this Guide is to explain the causes of variability in Rockwell hardness test results and to supplenment the information given in test method standards with .Learn all you need to know about Rockwell hardness testing – including test definitions, test calculations and insight into Rockwell hardness testing machines and HRC hardness testers – with knowledge and expertise from .

How to use the Rockwell hardness test for quick hardness testing in the lab or production environment. Vickers Hardness testing (HV) . A2LA Accredited Calibration Lab . Ensure your hardness testers are properly calibrated with direct and indirect calibrations according to ASTM and ISO standards. Brinell Hardness testing (HB) Knoop Hardness .Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing

1. Define Hardness. 2. Applications of Rockwell Hardness A ± Scale, B-Scale, C-Scale. 3. Type of Indentor used in the Three Different Scales of Rockwell Hardness Test. 4. Different Types of Hardness Testing Methods. 5. Size of the Ball to be used in Ball Indentor of Rockwell Hardness Test. 6. Di ameters of the different Balls used in Brinell .ASTM E110 is a test method for measuring the hardness of metallic materials using portable hardness testers that can determine both Brinell and Rockwell hardness. The test is conducted in the field or on parts that are too large or difficult to transport to a traditional lab.

The Knoop hardness test apparatus applies a controlled force for a specific time to an indenter in a rhombus shape (elongated four-sided pyramid). . I also trust LTI’s integrity and know that they will accurately report when testing does not go as planned. . independent testing laboratory and calibration company located in the suburbs of .

This article discusses rockwell hardness testing, its applications and uses. . a bachelor’s degree in journalism from Buffalo State College and has 8 years of experience working in a professional laboratory. . paper or report: APA. Smith, Brett. (2020, December 08). An Introduction to Rockwell Hardness Testing. AZoM. Retrieved on October .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. The Rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods .can somehow help rockwell hardness test gomez, ma. geraldine antoniette department of materials resources and engineering technology college of engineering and. Skip to document. . Rockwell Hardness TEST LAB Report. can somehow help. Course. Fundamentals of Materials Science and Engineering (MSE 301) 38 Documents. Students shared 38 documents . Keep your lab up and running with access to wear part kits and your machine being services by one of our highly trained Service Technicians. View Service Plans . Verification should be performed by an accredited verifying agency and the report should follow and reference ASTM E18 Rockwell test method. . Rockwell Hardness Testing Calibration .

Rockwell Calibration Sets; Rockwell Hardness Testers . pieces of steel, brass, or aluminum that have been specially heat treated and calibrated for consistency. By using a test block, Rockwell hardness testers can be calibrated for optimal precision. . ANSI (NCSLZ540-1, (ISO) 10012-1, ISO/IEC 17025, and ISO 6508, and they are certified in .

thickness measurement units

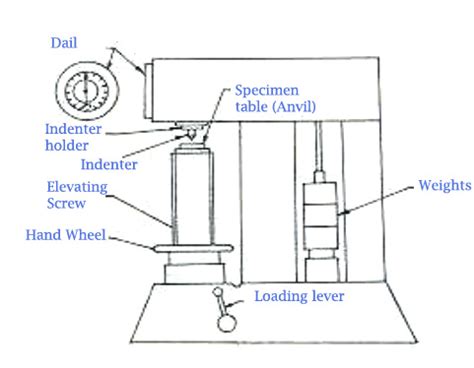

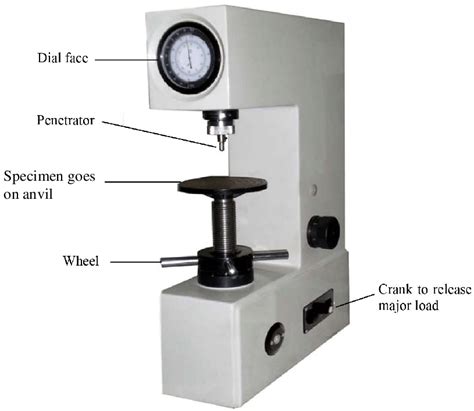

rockwell hardness testing machine diagram

Tester Calibration for Hardness Micro-hardness, Vickers, Knoop, and Rockwell hardness tester models are just a few of the hardness tester models that Infinita Laboratory is qualified and prepared to calibrate. Our professionals are capable of calibrating Rockwell hardness testers to C, B, A, and E scales. With the 15, 30, and 45 N&T Scales, a [.]Hardness is a property of a material to resist being indented. The Rockwell hardness test measures the depth of an indentation produced by an indenter due to the force/load applied. The hardness of a material is measured by the material’s ability to resist indentation. Therefore, a harder material will have a higher Rockwell hardness number.

9 Test report . ISO 6508-2:2015, Metallic materials — Rockwell hardness test — Part 2: Verification and calibration of testing machines ISO 6508-3:2015, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks 3 Principle An indenter of specified size, shape, and material is forced into the surface of a .1. To perform a calibration of a Rockwell hardness tester using a standard test block; and . 2. To measure the Rockwell hardness of a steel reinforcing bar, a widely used construction material. (b) Learning Goals: 1. To be able to perform Rockwell hardness testing, a .We proudly introduce our two companies namely, “Fine Manufacturing Industries” and “Fine Hardness Testing Machines Pvt Ltd.” We Fine Manufacturing Industries is one of the group companies of Fine group of Industries. We .

ISO 6508-1:2015, Metallic materials — Rockwell hardness test — Part 1: Test method ISO 6508-3:2015, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks 3 General conditions Before a Rockwell hardness testing machine is verified, the machine shall be checked to ensure that it is

Newage Testing Instruments is accredited in accordance with recognized International Standard ISO/IEC 17025:2017 General Requirements for the Competence of Testing and Calibration Laboratories. This laboratory also meets the requirements of ANSI/NCSL Z540-1-1994 and any additional program requirements in the field of calibration.ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir experienceandprovidinginformationforthisGuide.Theirinputandreview .4) For Rockwell hardness testing, no optical measurements are required; all readings are direct. There are two common methods applied to measure material hardness macroscopically: Rockwell and Brinell. Rockwell hardness differs from Brinell hardness testing in that the indentation size is measured in Brinell

SCOPE. The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.

Rockwell Hardness Test; The Rockwell test differs from the Brinell and Vickers tests is not obtaining a value for the hardness in terms of an indentation but using the depth of indentation, this depth being directly indicated by a pointer on a calibrated scale. The indenter of hardened steel ball or diamond cone can be uses in the Rockwell test.

Portable Rockwell hardness testers are available, which allow for on-site or field hardness testing. This is advanta-geous for applications where it is not feasible to transport samples to a laboratory or for situations that require imme-diate hardness assessment. Portable Testing 1.1The Buehler Wilson® Reference Block Laboratory in Binghamton, NY, has achieved accreditation to ISO/IEC 17025 by A2LA (American Association for Laboratory Accreditation) for Rockwell, Knoop, Vickers and Brinell hardness test blocks and indenters. A2LA is in full conformance with the standards of the International Organization for Standardization (ISO) .

rockwell hardness testing chart

ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application.Institute (NMI) for hardness, and as such, is responsible for traceability in hardness measurements. Objective Impact and Customers • Hardness is the most commonly used industrial test for quality control and acceptance testing of metals and metallic products. • Of over 12 000 ASTM standards, hardness test method standards are5.2.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. 5.2.2 In the Rockwell hardness test the preliminary test force is 10 kgf (98 N). Total test forces are 60 kgf (589 N), 100 kgf (981 N) and 150 kgf (1471 N). In the Rockwell superficial

corneal thickness measurement

Resultado da 119K Followers, 25 Following, 50 Posts - See Instagram photos and videos from Delfina Suárez (@delfinasuarez_official)

rockwell hardness test calibration lab report|rockwell hardness tester calibration cost